Smart Stickers

Digitally Enabling Everyday Products

November 2015

Abstract

The future of technology is the expansion of the web to be electronically and physically world wide. This means having electronics and the internet help us in all aspects of our everyday lives. This trend began with the prevalence of cell phones and personal computers. It is expanding through items like high-tech pedometers (fitness trackers such as FitBit, Misfit, Jawbone, etc.) and smart thermostats (Nest, Ecobee3, and Honeywell’s Lyric). While these products add wireless functionality to bits and pieces of our everyday lives, they require an expensive product upgrade and their reach is limited. There are still plenty of items in the home that have not received such upgrades, and even when they do the cost will prevent the upgrade from being readily accepted. Not everyone will want to buy a whole new washer and dryer set because it can connect to the internet. This is where the Smart Sticker solution comes into play. It provides a cheap, fast, and unobtrusive way to digitally update one’s life. These electronic stickers are programmed to assisted in daily tasks, and can be placed on any items to help update them. By combining existing RFID technology with computers and the internet, Smart Stickers create a bridge between a mechanical past and a connected future.

Introduction

In 1999, Kevin Ashton predicted an “Internet of Things” while at MIT. It is a system where the internet directly connects to the real world through a multitude of sensors. This idea has been gaining popularity for the past 15 years and has flourished in objects like smart phones, automotive technologies, and personal electronics. The experiments of home appliance manufacturers to incorporate the internet of things into their products have proven unappealing so far, such as Samsung’s attempt to enable refrigerators with an LCD display and FaceBook integration. The computer revolution has focused on improving existing hardware systems, i.e. screens and their accompanying computers, and further incorporating them in everyday life. To achieve a successful internet of things, however, all types of hardware must be utilized. The Smart Sticker concept is a departure from complicated hardware and strives to deliver maximum functionality with minimal computational or visual effort.

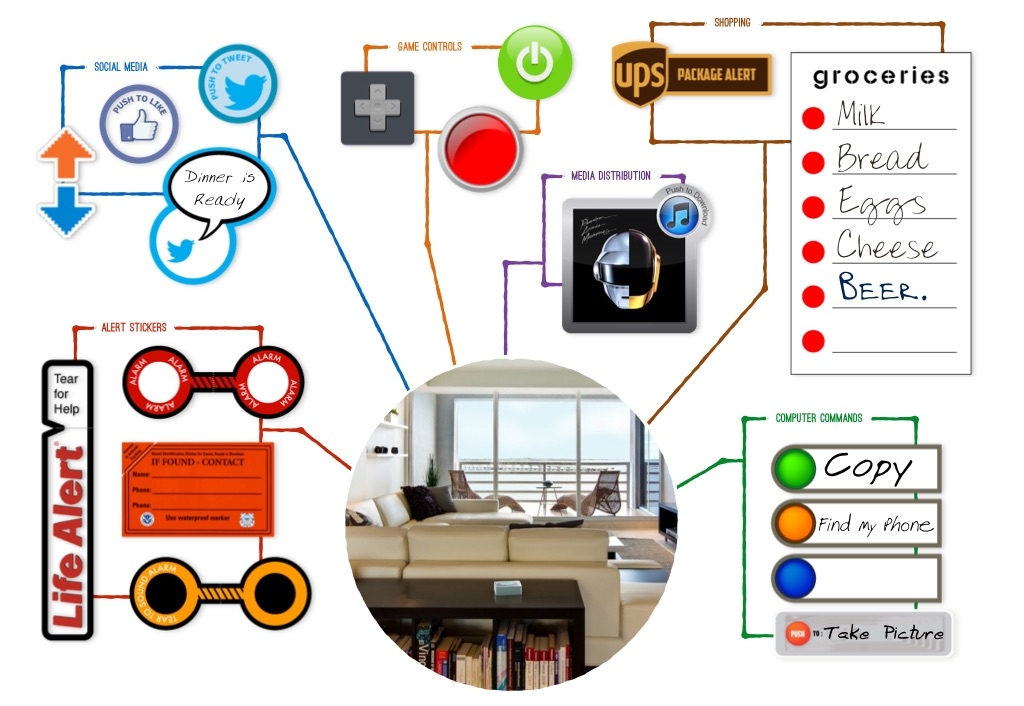

In order to take advantage of this connected future some industries are designing “smart” or “connected” devices. Smart devices use apps or app-like interfaces to make a product more functional for the user. An example of this would be a refrigerator that processes your shopping lists to inform you what you need to buy at the store. These devices are more expensive, not user friendly, and prone to premature obsolescence. While these clunky devices are developing, there is an ever increasing array of tools and services available online, few of which are capable of interfacing with traditional appliances. These tools and services include Twitter, Uber, iTunes, Facebook, Venmo, and more. (Fig 1.1) The only appliances they easily interface with are electronics like phones and personal computers.

The relatively low cost of developing software affords the developers and consumers a much shorter upgrade cycle. In stark contrast with this breakneck pace, home appliances have had very few functional improvements over the past fifty years. For example, the basic functionality of a traditional refrigerator has been unchanged since the 1940s. There is now a place in the market for an inexpensive method to retrofit these devices with a way to take advantage of new digital technologies. This type of retrofitting brings technology one step closer to a full Internet of Things.

How the Smart Sticker System Works

The main user experience is simple: someone buys a sheet of Smart Stickers, just like they would regular stickers. These stickers, however, come with an RFID tag embedded in them. Then, the user sticks the smart stickers to whatever surface is relevant. An application, tap, or tear of the sticker is enough to send it into action. This instant installation is possible with a pre-installed base station reader, which is performs all of the processing required.

A centralized interrogator, or base station reader, will scan for RFID tags. This reader is meant to blend into the home, much like current modems and routers (Fig. 2.1). The visual similarity between the base station and routers is meant to mirror the functional similarity between the two. Both devices are a central hub in the household that connect to the internet. The difference, however, is in what devices they connect to the internet.

The base station connects the stickers to the internet through a series of preprogrammed commands. When a new sticker tag is identified, the base station reader will run the ID number through an internet database, searching for an associated command. That command is then added to the base station’s list of tasks. Once the base station can no longer detect a certain RFID code, it performs the associated task. Frequently the task is performed by contacting the user’s cell phone, as this is how most people quickly connect to the internet.

The stickers themselves are not as complex. They feature the sticker’s image layered on top of an RFID button and a glue backing. (Fig. 2.2) The paper used, however, is a key component. The paper used for the stickers’ face and the paper used for the stickers’ backing acts as a damper, sandwiching the RFID chip and completely blocking its signal. Once the sticker is removed from its backing, the RFID chip is free to transmit its signal to the base station.

Together, the system works once the base station is installed and the stickers are placed on surfaces throughout the house. When a user deactivates the sticker’s RFID signal, which can be accomplished through different methods (Fig 2.3), the station picks up on that and performs the task assigned to that sticker. These stickers could be

placed on anything and be used in a myriad of ways. A sticker on a dryer could notify the user that their laundry is dry via text. This can be done with a simple timer; if the user presses the button immediately after starting an hour long dry cycle, the interrogator will know to send a text in an hour. A sticker on a refrigerator could add preset items to a shared digital grocery list. The user simply presses the assigned button once they are out of a specific item, and the interrogator adds the item to whatever app hosts this shared list. Reordering supplies in a warehouse could be completely streamlined; a sticker placed near inventories could be activated to purchase new items when supplies are low. Each sticker would be assigned to a single product, and when the sticker is pressed the interrogator would place an order for that one item.

Types of Stickers

Smart Stickers vary in both function and activation. (Fig 3.1) The different activation methods can be divided into three main types of sticker: stickers whose presence elicit a response from the base station, stickers whose damage elicit a response from the base station, and stickers that require interaction to elicit a response from the base station. These three types are enough to assist social media, video games, shopping, media distribution, security systems, and personal electronics.

“Present” stickers can be used as a notification system. They are stickers that cause the base station to execute a command simply by being present. One type of this sticker is a UPS package alert sticker. By placing the sticker on the package when it is delivered, it triggers a phone alert as soon as it is detected. The sticker can then be disposed of along with the rest of the unwanted packaging.

“Damaged” stickers are useful for safety and alarm. The RFID chip within them runs through a perforated or weakened section of the sticker, cutting off the signal as soon as the sticker is damaged. When the base station detects that the specific RFID chip is no longer present, it performs the associated command. These commands could include calling emergency services via life alert, notifying the user that a seal on a door, window, drawer, etc. has been broken, or as a way to notify someone as to where their lost luggage is.

“Interactive” stickers are the largest category of Smart Stickers. They house a button that temporarily shuts down RFID transmission when pressed. They allow the same action to be performed multiple times, which is useful in a variety of settings. Social media could use them as a real world like button. Pressing the sticker would add a “like”, “upvote”, “favorite”, etc. to real world places and things. Urban art could be connected to its social media presence or restaurants could get positive reviews without the user having to go to any specific website. Interactive stickers are also capable of turning any device into a game controller. As long as there is a display visible nearby, the button on the sticker can trigger an input.

Radio Frequency Identification

The smart sticker solution is based on RFID technology. Radio-Frequency Identification (RFID) is a method of wireless communication between an object and a computer. This system is an offshoot of RADAR, radio to computer communication developed during World War II1. Since then, it has become ubiquitous in our everyday lives. Its first commercial use was to tag cattle. This allowed herds to be wirelessly monitored. The technology spread from farming to shipping, when it was placed in packages and used to wirelessly track the packages’ location. Automotive and aerospace manufacturers have also embraced the technology as a part of the manufacturing process. By using RFID to track pieces during the assembly process, manufacturers have increased the efficiency of production. While all of these uses focus on location and tracking based problems, RFID is capable of much more than that.

RFID works off of a binary system. Each tag acts as an electronic barcode, transmitting its presence. This means it has two states: present and absent. A central system, called an interrogator, scans for the barcodes, and notes their presence. Because the system can only scan a certain distance, the location of the RFID tag can

also be inferred as within the range of the central system. Currently, most RFID uses only check for the presence of a tag. RFID can be used for much more, however, if a command is assigned to each tag. This makes it the perfect candidate to become a part of the internet of things. The interrogator can be small enough for home use and still be programmed to execute commands when RFID tags are detected.

RFID tags are simply antennas attached to microchips. In order to function, they require a separate console, an interrogator. The interrogator has two main parts to its design: a broadcasting antenna and a receiving antenna. It uses the broadcasting antenna to emit a radio wave that interacts with the antenna in the RFID tag. The interaction of the radio wave with the tag creates enough current through the antenna to power the microchip. The microchip transponder modifies the radio signal and reflects the new signal back using the power from the initial radio broadcast signal. Each tag modifies the broadcast frequency differently thus allowing the basestation to identify the individual tags. There are three basic types of these tags: passive, active, and battery-assisted passive. Passive RFID tags use the power of the initial radio wave to alter and reflect the interrogator’s signal. The alteration is specific to each tag and assigned during manufacturing. This action is powered with energy from the interrogator’s signal. Active RFID tags are able to alter and transmit their own signal.

Rather than waiting to receive a signal from an interrogator, the battery provides enough power to constantly send out a signal. Battery-assisted passive RFID tags have a built-in battery to assist their performance. They still have to wait for an interrogator’s signal to activate, but the built-in battery speeds up the internal processes and allows for transmission over longer distances. Smart Stickers are based on passive RFID tags, as this allows the stickers to function as long as the RFID chip isn’t damaged.

In addition to these three categories, RFID tags can be further organized by their range. Each basic type of RFID can be low frequency, high frequency, or ultra- high frequency. Low frequency RFID transmits a signal between 30 KHz and 300 KHz. Low frequency RFID is more stable around liquids and metallic objects and was chosen for initial testing to reduce the number of variables. Unfortunately, it had a slower data transmission speed and a maximum range of one meter. In a more advanced production, however, ultra high frequency RFID tags would be used. Ultra high frequency RFID tags operate between 300 MHz to 3 GHz and have a much larger operational distance and faster data transmission speed.2 They are less stable around liquids and metallic objects but with clever, beyond my technical abilities, engineering a suitable antenna and tag design is possible. The current state of passive ultra high

frequency RFID interrogators is around 10 to 15 meters. 2 Currently a single home wifi router has a maximum indoor broadcast range of about 50 meters.3 Using WiFi as an example of standard operational expectations, in order to function in a standard American home the Smart Sticker system would require powered signal boosters or a yet-to-be-determined engineering feat.

Manufacturing

The main component of a Smart Sticker is the RFID circuit sandwiched in- between two pieces of paper. If a traditional RFID chip were to be used in these stickers, they would be far too bulky to pass as a traditional sticker. This is unacceptable, as Smart Stickers are meant to be simple and unobtrusive. In order to create flat and thin stickers, the RFID circuit will be flash sintered onto the sticker backing. Flash sintering is a new manufacturing process that fuses nano-sized particles of material onto a substrate. Sintering itself is an already established manufacturing process, but normal sized metals require high and constant temperatures to rise above their recrystallization point and sinter successfully. Nano sized particles, however, can be excited with a high intensity flash bulb to reach their recrystallization point. This means that a finely deposited pattern of nano particles, applied through silk screening or inkjet printing, can be almost instantly turned into the conducting component of an RFID antenna array. Because the method used for sintering is a flashbulb rather than a high-heat application, the conductive layer can be deposited onto a flammable material like paper.

The Brinkman Lab, a manufacturing facility at Rochester Institute of Technology, is working on developing semiconductors and insulators (the components of a circuit board) that can be deposited in the same way. Theoretically, the entire RFID circuit and processor could be printed onto the sticker in one streamlined process. This new manufacturing method, not yet utilized in consumer products, could be commercially pioneered by the Smart Sticker system.

While flash sintering is in it’s infancy now, this emerging technology will fundamentally change manufacturing by providing a new element to consider in the design process. This prediction is supported by similar industrial developments, such as the invention of modern transistors. Circuits originally required vacuum tubes rather than transistors to control the current flowing through them. The size of the tubes meant that any electronic device utilizing circuits was large and bulky. In 1947, the first transistor prototype was built out of gold foil pressed into germanium. This setup was much smaller than traditional vacuum tubes, allowing the size of electronics to shrink drastically. It was only seven short years before Texas Instruments was commercially producing electronics developed with transistors.4 Nuclear technology advanced through a similar developmental process. The gap between the first controlled fission reaction and the first nuclear power plant was only nine years.

This first nuclear reactor could barely power a light bulb, but was successful in the providing a new method for producing power. Improving on this infant idea, the first power plant was built less than a decade later. This brand new energy source fueled an entire city for over fifty years.4 Flash sintering is in the same infancy. Much like the gold and germanium transistors or the tiny fission reactor, flash sintering is a newly developed process that just needs a widespread application in order for it to develop rapidly. The Brinkmann Lab is developing a way for flash sintering to replace circuit boards, and Smart Stickers provide an application for that manufacturing process. Flash sintering technology is reaching sufficient levels of advancement to be economically viable in consumer products.

Design Goal

The main goal of this project is not to sell a product, but to set up a system. While it does involve the design and manufacture of new products, they all work together to contribute to the aforementioned internet of things. In order to support the growth of the system, it is meant to be produced by multiple parties. It would start out with a single manufacturer producing the base station and a limited selection of stickers. After the growth of the core system, it will be easy for third parties to create their own stickers and expand Smart Sticker usage. Ideally, many different markets will find a use for this type of automation.

The Smart Sticker is also an effective way to contribute to the internet of things while minimizing the dangers of obsolescence. Because RFID technology is well established and has not changed drastically in recent years, compatibility issues between different generations of stickers will be minimized. The system is instead set up for growth and adaptation to everyday life. While Smart Stickers will at first require a centralized interrogator to connect to the internet and then phones, the future of Smart Stickers could cut out the middle man. If they become popular enough, phones could be designed with RFID scanners built in, similar to cameras and GPS trackers.

Smart Stickers are not only meant to be ubiquitous, but also to be invisible. Their aesthetic is meant to blend in with current technologies while adding futuristic functionality. It is important that Smart Sticker technology disappears into the fabric of daily life rather than becoming a center focus. It achieves this by mimicking products that are already a part of our everyday lives. Routers and stickers can be found in most homes, so a Smart Sticker home will not look any different. The only change will be a simplification of people’s lives.

Development

While most of this project was system-based and required little physical development, the technology for the stickers needed proof of concept. This was achieved by testing the sticker materials and the system’s circuitry. The circuits tested could have been made with either copper or silver, but copper was chosen for its price point. The Brinkmann Lab provided sample flash sintered RFID tags, which were then tested with different paper substrates to see which would be most effective for the sticker. Tyvek was the first material tested in an attempt to create a waterproof sticker, but it could easily stretch and break the circuit. Regular sticker paper proved to be more fitting for the task, and presented no problems.

Producing and testing the base station was a more technologically intensive task. A breadboard was used to create a sample RFID chip and reader. The reader was composed of an LED, an antenna, and a micro-controller. After researching what type of antenna worked best for picking up on RFID signals, one was constructed using specific lengths of wire. The antenna was connected to a micro-controller that was programmed to read the signal and perform a command when the signal was lost. In this case, the command was turning on an LED. An RFID circuit was set up as well.

This circuit tested the antenna’s functionality, and once the signal was verified the circuit was broken. After some debugging and troubleshooting, the LED turned on and proved that the loss of a signal could trigger a command. The circuit was also tested in household conditions that might affect its performance, such as being placed near a microwave. This proved the concept for the damaged stickers, but not the interactive ones.The mechanism inside the interactive stickers worked, but the base station didn’t have a fast enough refresh rate to pick up that the RFID circuit had been broken for a short amount of time. By the end of the project, this problem remained unsolved.

User testing development was minimal, as very few human factors needed to be accounted for. The alarm style stickers were tested with users because they had a mechanical component as well as an electric one. In this case the stickers had a paper section that needed to be ripped. The stickers tore easily when placed over a seal. The rest of the product functions like a regular sticker, just peel and stick.

Conclusion

The goal of the Smart Sticker thesis was to create a functioning prototype, a goal that was only partially reached. The final prototype was an RFID sticker and a base station, but the RFID sticker used a regular RFID tag rather than a flash sintered one. To take this basic prototype to the next level would require both engineers and development funding, neither of which are feasible by the writer at this time. The system for the sticker, however, was sufficiently developed to demonstrate viability.

The Smart Sticker is a system worthy of further development due to its wide array of benefits. It utilizes and popularizes a brand new manufacturing method, helps to fight against premature obsolescence, and also brings technology one step closer to a full internet of things. The viability of a smart sticker system was proven with Amazon’s Dash Button, which was released after this thesis was completed. The usage is very similar to a smart sticker; it is a button placed near an item that performs one task related to that item. In the Dash Button’s case, it orders an item from Amazon. The development and release of such a product from a company as large as Amazon shows there is merit to the Smart Sticker system.

Smart Stickers fully utilize existing appliances by connecting them with the internet. Stickers have always been a way to customize belongings, but flash sintering allows for something far more than just aesthetic modification. Although bringing flash sintering into mainstream manufacturing is a challenge, it has the potential of revolutionizing circuit manufacturing. The possibilities are so broad they require a widespread user base, like that of Smart Stickers, to uncover the majority of them. With any luck, this product will leave people better off and inspired.

Landt, Jeremy, and Barbara Catlin. Shrouds of Time The History of RFID. Publication. Pittsburgh: AIM, 2001. Print.

Impinj. The Different Types of RFID Systems. from http://www.impinj.com/ resources/about-rfid/the-different-types-of-rfid-systems/. Seattle: Impinj, Inc, 2002-2016. Web.

Apple. Airport Express Specifications. from http://www.apple.com/airport- express/specs/. Cupertino: Apple Inc. 2015

Gertner, Jon. The Idea Factory: Bell Labs and the Great Age of American Innovation. New York: Penguin, 2012. Print.